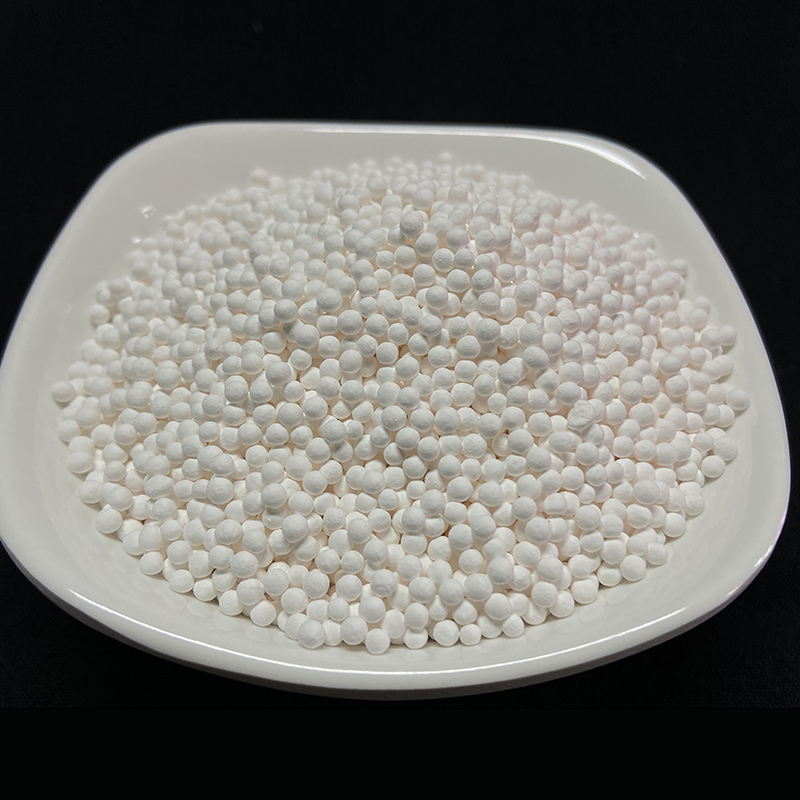

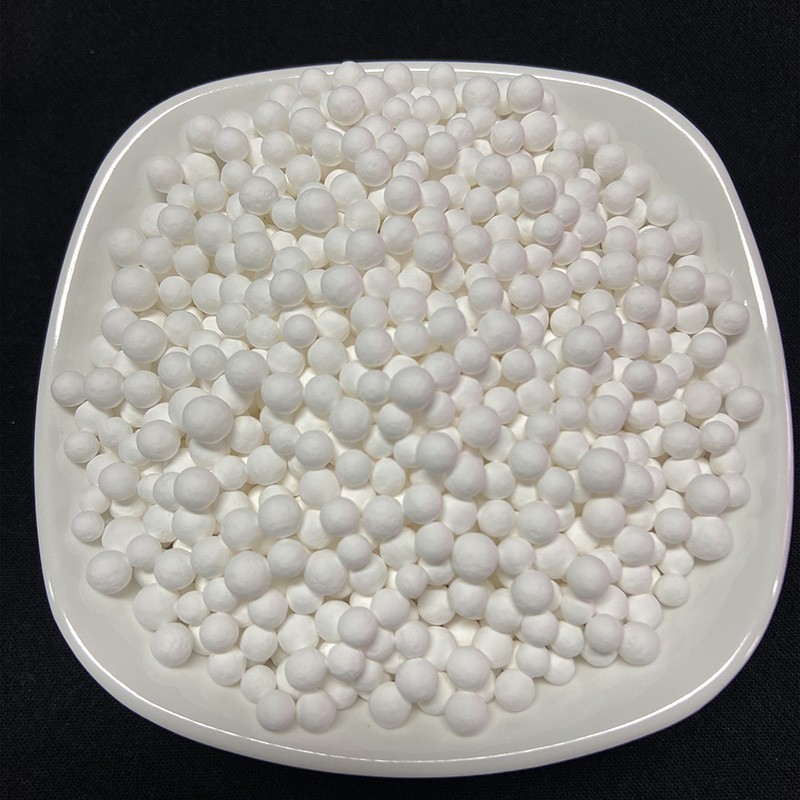

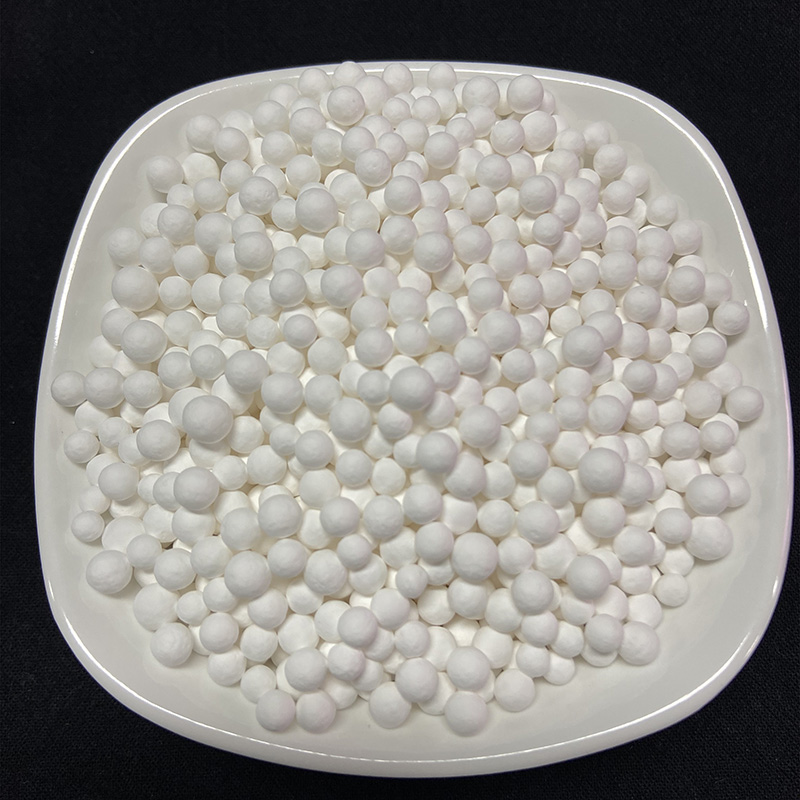

Alumina Ceramic Filler High Alumina Inert Pob / 99% alumina ceramic pob

Lub cev thiab tshuaj muaj zog ntawm Inert Ceramic Balls

| Lub cev thiab tshuaj muaj zog ntawm inert ceramic pob | |||||||

| Element | Al2O3% | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3% | ≤0.9 | ≤ 0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| Cov khoom seem tuaj yeem txiav txim siab los ntawm kev sib tham ntawm tus neeg muag khoom thiab tus neeg yuav khoom thaum tsim nyog. | |||||||

| Kev nqus dej, % | 3 ± 1, Nws tuaj yeem txiav txim siab los ntawm kev sib tham ntawm tus neeg muag khoom thiab tus neeg yuav khoom | ||||||

| piv, kg/m³ | 2.5-3.0 Nws | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Qhov ceev, kg / m³ | 1400-1550 Nws | 1400-1650 Nws | 1500-1800 Nws | 1700-1950 Nws | 1800-1950 Nws | ≥1900 | |

| Plua plav, tawg lossis tawg | Ib lub hnab tsawg dua 5% | ||||||

| Qhov txawv txav | Uniform kheej kheej, qhov piv ntawm qhov loj tshaj plaws mus rau qhov tsawg tshaj plaws txoj kab uas hla ntawm ib tug ceramic sphere tsis tshaj 1.2 | ||||||

| Dimensional kam rau ua | ≤10mm | ± 1.0 | |||||

| 11-25 hli | ± 1.5 | ||||||

| 26-50 hli | ± 2.0 | ||||||

| ≥50mm | ± 3.0 | ||||||

| Dawb lub zog poob | Lossless tus nqi ≥99% | ||||||

| Compressive zog | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| xwm 75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 : kuv | 55-75 : kuv | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Hnav tus nqi% | ≤ 2 | ≤1 | |||||

| acid solubility, % | ≤ 6 | ||||||

| Alkalinity, % | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Refractoriness, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Resistant mus rau qhov sib txawv ntawm qhov siab | Tsis muaj kev puas tsuaj ≥ 99%, tsis muaj kev hloov pauv hauv compressive zog thiab siab tom qab hloov tam sim ntawd tsawg dua 25% | ||||||

| Resistant mus rau tam sim ntawd kub hloov | Lossless tus nqi ≥99% | ||||||

| Pob | Hlau nruas ntim | Ntim hauv cov nruas hlau, ntim nrog cov hnab yas PP lossis PE tuab | |||||

| Woven hnab ntim khoom | Muaj nyob rau hauv cov hnab tawv tawv thiab UV-resistant woven hnab | ||||||

| Nco tseg: Cov ntaub ntawv ceev ntau yog rau kev siv nkaus xwb, tsis yog lub hauv paus rau kev lees txais. | |||||||

Lwm Daim Ntawv Ceeb Toom: Saib Table 5 Rau Kev nqus dej ntawm 99 cov khoom ntim khoom

| 99 Filling Ball Water Absorption | ||

| 99 puv | txoj kab uas hla | txoj kab uas hla |

| yob txoj kev | φ25 hli | <5% |

| Tshuab xovxwm txoj kev | φ25 hli | <10% |

99.5% Technical Indicators

| Al2O3 | ≥99% |

| SiO2 | ≤ 0.14% |

| Fe2O3 | ≤ 0.04% |

| CaO + MgO | ≤ 0.03% |

| TiO2 | ≤0.06% |

| Na2O | ≤0.1% |

| K2O | ≤0.1% |

Physical Index Of Chemical Filler Ball

| TXOJ CAI | INDEX |

| load softening (yb/t370-1995) | Deformation nyob rau hauv 0.2mpa siab yog tsawg dua 0.6% |

| Thermal shock resistance (yb/t376.2-1995) | 1200 ° C mus rau 600 ° C. 10 zaug yam tsis muaj qhov tawg |

| Reburn kab hloov pauv (gb/t3997.1-1998) | 1400 ℃ rau 12 teev, tus nqi siab tshaj plaws yog 0.25%, tus nqi nruab nrab yog tsawg dua 0.20% |

| Ntau qhov ceev (gb/t2997-2000) | 3.2-3.50 g / cm33 |

| crushing zog | Raws li ntau tshaj 230 kg / cm2 |

| Pom tseeb porosity | 12-18% |

| Qhov ntom ntom | 2.1-2.3g / cm33 |

Tshuaj Packing Pob Pob

1) Ordinary packing: polyethylene woven hnab nrog net hnyav ntawm 25kg, ntxiv pallet

2) Steel nruas ntim: 100L steel nruas ntim, pallets tuaj yeem ntxiv